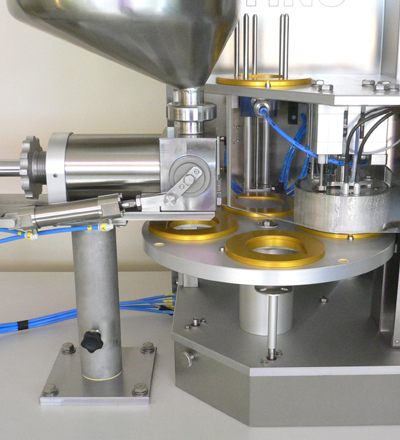

ROTINO

The cup-sealing machine with piston filler (CUPFILLER)

It's finally here! The great table-top model.

This cup-sealing machine ROTINO combined with our piston filler is more versatile than almost any other filling machine. The ROTINO is ideal for the sealing of cups with stamping lids or for sealing the catering cups with snap lids. It is quick to convert and can fill and seal various different packages with precise volumes.

Advantages of ROTINO:

- easy to clean

- format change in less than a minute

- versatile

- affordable

Mode of operation:

The ROTINO is a 4-component cup-sealing machine (rotary machine). The cups are filled by the CUPFILLER and automatically sealed.

The 4 ROTINO stations:

- Cup insertion/removal

- Filling (CUPFILLER)

- Automatic lid application

- Heat-sealing or pressing of lid

Operation:

The ROTINO is operated via a touch panel. Each function can be switched on individually. You have the option of working in single cycle - or of choosing the speed in automatic mode. Use the 4-value databases to save your product settings.

When you change the cup-size, the ROTINO helps you with the format change.

The CUPFILLER is a precise piston filler that is suitable for many different filling products. It is controlled through the ROTINO. The CUPFILLER can be disassembled in a few easy steps and cleaned to a hygienically faultless standard.

Technical specifications:

4 ways of using the ROTINO

Version 1: CUPFILLER fills in the ROTINO

Version 2: CUPFILLER fills alongside the ROTINO

Version 3: CUPFILLER is used separately

Tubs, bottles or jars are filled using the CUPFILLER and closed by hand.

This is an additional application of the CUPFILLER. Should you wish to provide products in containers which cannot be sealed in the ROTINO, you can use the CUPFILLER separately. With large containers you reach the desired volume through multiple filling.

Version 4: Using the ROTINO with additional devices

Combine ROTINO with another metering system.

The ROTINO provides a signal for an external device that allows you to control a different metering system. This makes it possible to dose other filling products for which the piston filler is not suitable (e.g. granular or highly viscous products).

Combine ROTINO with another device.

The signal can also be used for additional devices:

- Labelling device and printer

- Pre-meter and filling scale

- Conveyor belt, etc.

Using the ROTINO separately.

Of course you can also use the ROTINO separately, as a sealing machine or for applying plastic lids.

The ROTINO has a wide range of applications. We are happy to advise you.